Coolroom Door Seals and How They Work to Prevent Air Leaks in Cold Storage

- 11 November 2024

C&M Coolroom Services Melbourne explains how coolroom door seals prevent air leaks in cold storage, boosting energy efficiency and preserving product quality.

Coolroom door seals are vital for maintaining airtight conditions in cold storage units. They prevent cold air from escaping and stop warm air from entering, ensuring optimal temperature control. By preventing air leaks, these seals help reduce energy consumption and protect the integrity of stored goods.

The Importance of Coolroom Door Seals

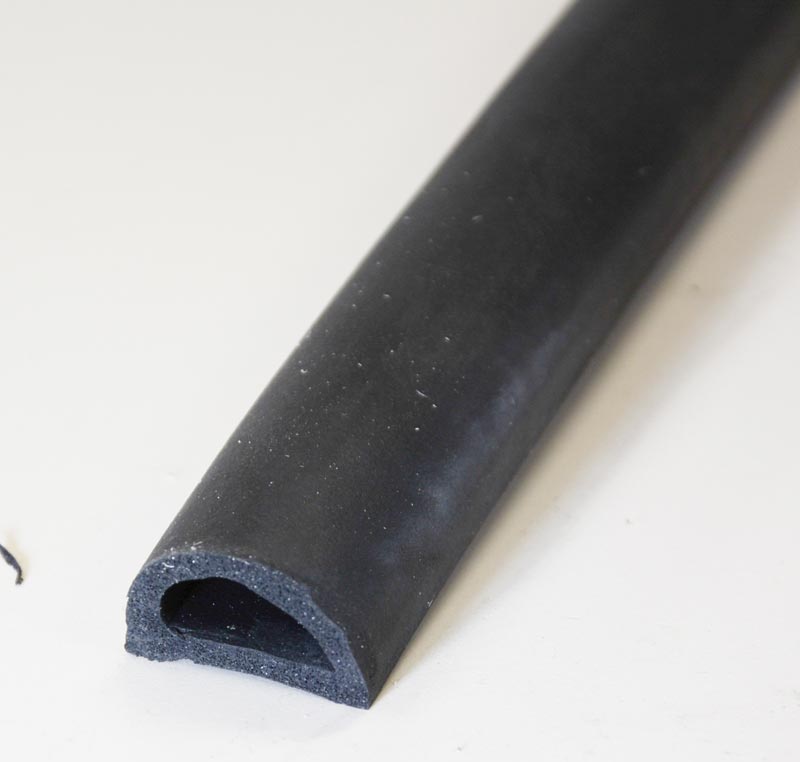

Coolroom door seals, often made of flexible rubber or PVC, are installed around the edges of doors to create an airtight barrier between the inside of the coolroom and the external environment. Without these seals, cold air can easily escape, leading to increased energy consumption as the refrigeration system works harder to maintain the desired temperature. Over time, damaged or worn-out seals can cause significant problems in terms of energy efficiency and product quality.

Here’s how coolroom door seals contribute to cold storage efficiency:

• Temperature Control: Seals help to keep cold air inside the coolroom and prevent warmer external air from entering. This helps maintain a consistent temperature, which is vital for the preservation of perishable goods.

• Energy Savings: By preventing air leaks, seals reduce the amount of work the refrigeration system has to do. This leads to lower energy consumption and reduced operational costs.

• Product Integrity: Temperature fluctuations caused by air leaks can lead to spoilage or degradation of products. Seals help ensure that the temperature remains stable, preserving product quality.

• Compliance with Health Standards: Many industries, particularly food and pharmaceuticals, must adhere to strict health and safety standards. Properly functioning coolroom door seals help businesses meet these requirements by maintaining appropriate storage conditions.

How Coolroom Door Seals Prevent Air Leaks

Coolroom door seals are engineered to create a perfect fit between the door and its frame, minimising the chances of air leaks. These seals are designed to compress tightly when the door is closed, forming a continuous barrier that traps cold air inside. This prevents the entry of warm air, which could lead to condensation, increased humidity, and a temperature rise. Seals can be magnetic or non-magnetic, depending on the type of door and the level of sealing required.

Key features of effective coolroom door seals include:

• Flexible Materials: Coolroom door seals are made from durable, flexible materials like rubber or PVC. They can endure constant door use without losing shape or effectiveness.

• Compression: The seal compresses tightly against the frame when the door closes. This creates an airtight fit, preventing air leaks.

• Resilience to Temperature Extremes: These seals are built to withstand cold environments without cracking. They remain effective even in extreme temperatures.

• Ease of Replacement: Worn-out seals are easy to replace when needed. This ensures the coolroom stays airtight and energy-efficient.

Signs That Your Coolroom Door Seal Needs Replacement

Regular inspection of your coolroom door seals is crucial for optimal performance. Signs that indicate the need for replacement include visible cracks or tears in the seal, difficulty in closing the door, frost build-up around the edges, increased energy consumption, and noticeable temperature fluctuations inside the coolroom.

Addressing these issues promptly ensures the efficiency of your cold storage system. Regular inspection and maintenance of coolroom door seals with C&M Coolroom Services are crucial to avoiding costly repairs and ensuring long-term performance.

Mark Connelly

C&M Coolroom Services

E-mail : markconnelly@cmcoolrooms.com.au

Mobile: 0412 536 315