Aluminium Coolroom Parts: Key to Increased Lifespan and Reduced Repairs

- 19 February 2024

Unlock the key to coolroom longevity with aluminium coolroom parts from C&M Coolroom Services. Enhance performance and durability. Call us at (03) 9401 3444.

Coolrooms are cold storage solutions that are often utilised in food storage, pharmaceuticals, and others to preserve the freshness and quality of perishable goods. While their importance is widely recognised, the components contributing to their efficiency typically go unnoticed. One of these components is the aluminium coolroom component.

Aluminium coolroom components generally stand out for their notable role in boosting performance and ensuring the longevity of these cold storage solutions.

Advantages of Aluminium Components

Aluminium has long been recognised for its exceptional properties, making it a preferred material in various industries. When it comes to coolroom fabrication, the use of aluminium components brings a wide range of advantages. Some of them are as follows.

• Lightweight: Aluminium is known for its lightweight yet robust quality. In coolroom construction, this quality of aluminium translates to structural integrity without adding too much weight, allowing for easier installation and flexibility in design.

• Durable: Coolrooms are at risk of corrosion due to temperature variations and humidity. The innate corrosion resistance of aluminium ensures that components remain durable and unaffected by these damaging environmental factors.

• Thermally Conductive: Efficient temperature control is the core of coolroom functionality. Aluminium’s excellent thermal conductivity facilitates effective heat transfer, which helps in maintaining the desired temperature levels within the coolroom while optimising energy efficiency.

• Hygienic: Coolrooms demand strict adherence to hygiene standards, especially those utilised in the food industry. Aluminium’s non-porous surface and resistance to bacterial growth make it an ideal choice for components where cleanliness is prioritised.

Key Aluminium Coolroom Components

We, at C&M Coolroom Services, offer a variety of aluminium coolroom components that can be useful for different industries.

Aluminium checker plates, for instance, are sheets of aluminium with a raised pattern of lines or diamonds on one side. This distinctive pattern provides them with additional grip, making their surface slip-resistant. They can often be utilised in coolroom flooring, walkways, and storage areas.

Another aluminium component we offer is the aluminium door capping. It refers to a protective and decorative covering that is often installed on the top edges of doors. Once installed in coolrooms, this component can help in temperature insulation, condensation prevention, hygiene maintenance, durability enhancement, and airtight sealing.

Aluminium coving is another component we offer to coolrooms. It is a specialised interior design element that can enhance the aesthetic appeal and functionality of coolrooms. Like aluminium door capping, aluminium coving can also enhance the hygiene, durability, and sealing of coolrooms.

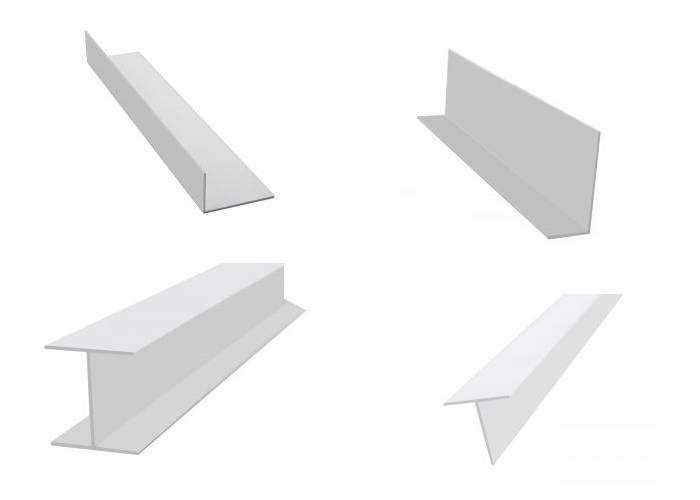

Other aluminium coolroom components we offer are beams, angles, base channels, beads and tubes.

In coolroom design and construction, aluminium coolroom components from C&M Coolroom Services can help contribute to enhanced performance, longevity, and overall efficiency. As you continue to prioritise sustainable and effective storage solutions, the role of our products in shaping the future of coolrooms becomes increasingly evident. So, whether you are in the food industry, pharmaceuticals, or any sector relying on precise temperature control, consider and invest in our aluminium coolroom products to significantly enhance your coolroom performance and lifespan.

Mark Connelly

C&M Coolroom Services

E-mail : markconnelly@cmcoolrooms.com.au

Mobile: 0412 536 315