Starting with an obvious observation, the team members who are responsible for taking apart a coolroom need to protect themselves. Granted, if this is a newer construct, it’s likely been designed to come apart easily. In other words, it’s modular. That being said, sharp edges will become exposed as the chamber breaks apart. Wear protective gloves and observe the following guidelines.

Electrically Isolate the Equipment

There are live electrical circuits humming quietly inside operational coolrooms. Even when the refrigeration equipment isn’t powered, perhaps because the thermostat isn’t active, there could be a dangerously high electrical charge nearby. Remember, this equipment requires a moderately high amount of power. Moreover, the chamber likely has lots of exposed metal parts. If an electrical shock does occur in here, it could prove fatal. Always safely isolate the circuits. Turn them off at the fuse board, pull the fuses, or lock down the circuit breakers. Even after all of those actions have been taken, a professional refrigeration technician will still want to test the circuits to make sure every live wire is safely depowered.

Relocating

the Refrigeration Equipment

It’s not hard to relocate the electrical wiring.

In point of fact, it might just be cheaper to rewire the whole thing. If the

wiring is kept, check the insulation for any abrasive scratching. If the wires

are damaged, they can’t be used again. Anyway, even while taking the

possibilities of wiring damage into account, this is still a straightforward

procedure. For the refrigeration unit, well, things can get a mite more

complicated. For starters, there’s the refrigerant to deal with when breaking

down the gear. A dismantling or decommissioning process can’t begin by ripping

the gear out of its ducting. No, the fluid has to be depressurized and

discharged. There are refrigerant recovery protocols to observe, plus the

storage/transferring equipment to purchase. Then, if this really is a

decommissioning job, there might be an environmentally harmful fluorocarbon

load to safely dispose of, as regulated by a nationally accredited ruling body.

In order of personal and environmental hazards, the electrical dangers come out

on top. They’re more immediate, for high electrical currents can kill

instantly. Next, an environmental hazard exists as a charged refrigerant load.

The fluid needs to be discharged and valves need to be sealed. The recovery

procedure clearly requires the services of an expert engineer. This is no job

for an amateur. Finally, mechanical dangers are easier to pinpoint. Sharp edges

can cut sensitive skin while heavy walls can crush limbs. Incidentally,

unforeseen hazards are always lurking. Wear a breathing mask, just in case the

wall insulation contains dangerous fibres. That mask will also provide

additional protection, should dangerous bacterial spores be concealed in those

wall panels.

If a

coolroom’s layout is optimized, yet the equipment’s still drawing way too much

electrical energy, something’s still not right. Odds are the refrigeration unit

has some kind of a performance frustrating issue. Even more frustrating, this

issue is ongoing. It’s not getting any better, and it won’t until someone

tracks down the energy siphoning cause. Calling in an expert service engineer,

that pro-worker should head straight to the equipment coils.

Obstructed Refrigerator Coils Cause Energy Losses

Indirectly

speaking, the icy build-up hampers coil efficiency. Perhaps there’s excess

moisture coming off of a row of frozen meat, or maybe the region in which the

coolroom resides is naturally humid. Whatever the reason, the excess moisture

condenses when it comes in contact with the evaporator coils. And it’s not

going to stay that way for long. After the condensate forms, it freezes. Over

and over, this cycle repeats until a thick layer of ice impacts the cooling

mechanisms heat transferring functions. Meanwhile, over on the condenser coils,

dirt and debris have a similar effect on the heat release stage. Without a

fully exposed condenser, the refrigerant can’t cool and condense efficiently.

Coil Restoration Methodologies

It’s nice to know that a little warm water and soap can restore a complicated assembly of technologically advanced electro-chemical parts to their functional best. Instead of replacing a hard to get at compressor unit, the servicing team just washes the dirt off of one coil while someone else removes the ice from the second set of coils. Only, hold on, it’s not quite that straightforward. To really restore heat transference performance, elbow grease isn’t enough, not even with a bucket of hot water. In reality, when refrigeration companies offer a coil restoration service, they’re talking about powerful steam equipment and cleaning agents. Applied as a multi-stage system rejuvenation process, steam and non-corrosive cleaners soften and-de-bind the ingrained dirt.

There’s outside work to be done. The vents and filters require cleaning. If they’re filthy, a few replacement parts will soon fix things. That same approach won’t work on the condenser coil. Likewise, after the ice has been carefully melted off the evaporator coils, there are still traces of muck and gunk coating those exposed parts too. A run-of-the-mill coolroom servicing company might try that warm water and soap approach, and they might even have limited success. Stepping up to the next level, a genuine coil restoration assignment uses proprietary coil cleaning techniques, which may or may not include steam ablation technology. With coil performance back to its functional best, advanced auditing and data collection instruments make sure coolroom efficiency is maximized.

Contrary

to popular opinion, refrigeration services don’t always place a heavy focus on

cooling equipment. Admittedly, that’s their raison d’ê·tre, their main role in

life, but this is a profession that covers many different engineering

disciplines. Why, there are even times when C & M Coolrooms technicians

find themselves repairing or replacing heating cables.

Where Are The Heating Cables?

Warming

wires of this type can be found in several locations. Before going any further,

however, these aren’t true heating elements, they are radiant fractional

amounts of thermal energy. For example, a cold concrete floor could crack

because of the minus 20°C temperatures inside a deep-freeze unit. Worse still,

there might be groundwater under the concrete. It’ll freeze, the ice will

expand, and the concrete will crack again. Door seals also need wired heating.

Trace heating wires thread their way around door frames so that a rime of ice

doesn’t cause the door to stick. Last of all, heating cables can be wrapped

helically around all sorts of fittings, including ducts and pipes.

Replacing Damaged Or Aged Thermal Cabling

The tiny

amounts of energy are enough to stop a floor cracking or prevent a door from

accumulating frost damage. Unfortunately, just like any other equipment

fitting, these insulated electrical wires do have a limited lifespan.

Admittedly, it’s not going to be easy to replace underfloor cables, not unless

they were installed in tubular conduit. One solution to this issue is to

replace the underfloor cables with rubberized mats. The knobbly pattern on

those rubber sheets insulates the floor while also acting as a slip prevention

aid. For the broken door seal, a replacement heating cable is far easier to

replace.

Portal Frame Wiring Replacement

The technician turns

off the power, as the circuit may still be live, even though it’s no longer

functioning. A continuity test with an electrical multimeter should be used

next. If the circuit is damaged, the tech puts on a pair of gloves, exposes the

wire, and carefully removes it from the door edges. A replacement cable, one

that uses the same electrical specs, is now substituted for the damaged heat

tracing. Remember, the lip of the door may seamlessly connect to the unit’s

insulation panels. If that’s the case, a C & M Coolroom technician should

be called out to carry out the work.

Interestingly, there are new underfloor options on the horizon. Heating cables

are still clearly the superior option. Only, they can be impossible to replace.

One solution involves running them through buried metal conduits. A second idea

is to use a piped fluid, such as glycol. Transporting trace amounts of heat

into the floor, there are no moving parts to fail in a fluid-based underfloor

heating system.

When you are building your business, you know that you want to incorporate the best materials and equipment possible. Whether you are filling out a pharmaceutical building or you are preparing a commercial kitchen, you’ll likely need to lean on the services of a coolroom. Coolrooms are an integral addition to any facility where temperature control is of the utmost importance. Coolrooms aren’t just big, cold rooms, however. Instead, coolrooms can be a vital part of the work that you are doing. Today, we are going to go over the benefits of installing customised shelves and racks to your coolroom.

Enhancing Your Coolroom

Your coolroom can be as sparse or as densely populated with features as you desire. In the scenario that you are setting up a commercial kitchen, you’ll likely want to have some customisability when it comes to your room. Your coolroom will likely need to have shelves and racks in order to separate ingredients or to keep foods prepared. Likewise, a pharmacy will want to keep their temperature-sensitive products in a clean and organised environment. As a result, coolrooms can benefit from professionally installed racks and shelvings. With that being said, why should you turn to a professional installation team to handle the job?

1) Tailor Made Solutions – Here at C&M Coolroom Services, we work hard to deliver you the coolroom solutions that are specific to your business and your needs. No two buildings are identical and no two businesses have the same exact needs. When you hire our professional team of installation techs, we are able to give you exactly what you need while treating you like the individual that you are.

2) Professional Installation – When it comes to doing something important, you might as well do it right. Here at C&M Coolroom Services, we have years of experience on our side. There is no job too big or too small to prevent us from delivering ou the kind of professional, accurate, and efficient installation that you need. With years of expertise on our side, we are more than ready to deliver you a coolroom customisation solution today.

3) Professional Product – Finally, when you call on C&M Coolroom Services, you are getting a professional product that meets and exceeds all expectations. We work with the best materials possible for our coolroom racks and shelving installations. We are delivering you a product that is durable and will last longer than a conventional installation, thus providing you with the organisation abilities that you need.

When you are ready to take your coolroom into your own hands, give us a call. Our qualified technicians are more than ready to walk you finding the right racks and shelving for your coolroom.

Somewhere out there, a custom-built walk-in freezer has rejected its cookie-cutter layout. Elsewhere, perhaps in a remodelled supermarket, a designer has used out-of-the-box design practices to construct a glass-doored coolroom that looks appealing. Behind the steel and glass framing, beverage stockers are working unobserved. Clearly, singular designs, custom-designed coolrooms satisfy every conceivable client stipulation. However, for every unique system layout, an equally unique problem can develop.

Avoid A Super Streamlined Layout

Perhaps the cold room is going up in a smaller than average piece of floor space, or some interior designer believes the time has come to develop a super-skinny walk-in unit. Well, coolrooms are airy spaces for a reason. They use that space to maximize system airflow and ensure every item has access to its own stream of chilled air. A custom-designed interior layout is welcome, but the visually appealing stylings cannot take precedence over the airflow factor. Of equal importance, stylish doors and slender system air intakes are allowed to assume tailored profiles, but that shape cannot interfere with their functions. A sealed walk-in freezer door keeps its interior safely chilled and energy-efficient. Likewise, an air intake panel doesn’t experience the custom-designers’ scalpel, not in a way that would impair its air channelling features.

Seeing Through The Blank Palette Illusion

It’s easy to make this mistake. Someone goes inside a typical walk-in unit and sees its featureless build. It’s a blocky construct with a concrete floor and a powerful refrigeration unit. Completing the design, a sealed access portal and a thermostat deliver a spartan but functional build. Surely, if a designer was let loose, all kinds of build factors could be configured to suit a particular application. To a point, that’s an accurate statement. But the tailoring work can’t overrule a key set of engineering-oriented design factors. Alter the dimensions and shape of the space, but don’t obstruct airflow by adding too many twists and turns. Always adopt a form follows function design philosophy.

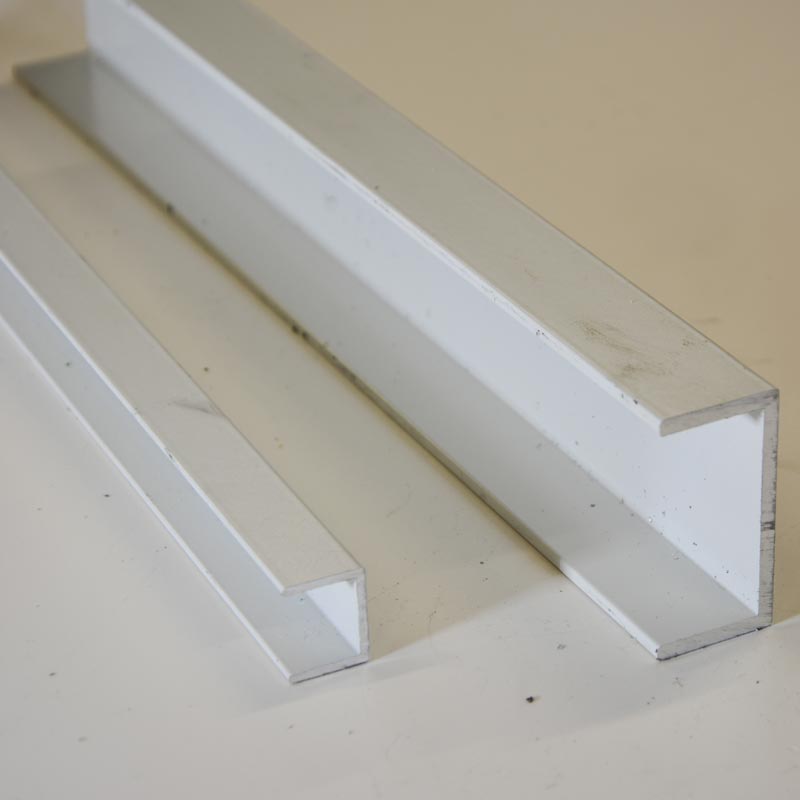

To label those basic factors, let’s break a custom-designed build down. Dimensional changes are feasible, but the alterations can’t impact safe airflow distribution levels. For tailored doorways and venting/inlet requirements, the refrigeration unit needs access to an uninterrupted volume of outdoor air, and the door seal must maintain this carefully controlled thermal low. Likewise, a custom-designed bank of insulated wall panels can gain an embossed pattern of some kind, but that aesthetic appeal can never be more important than the composite materials that insulate the walls. At the end of the day, functionality isn’t just a convenience here, it’s a hygiene safeguarding guarantee. That feature can’t be undermined, not even by a custom-designed layout.

C&M Coolrooms can create a custom solution for your specific needs. Talk to one of team members today.